Chop

Win32 and 64, EnglishGeneral Usage Instructions

Beforehand, you can make all the settings in the AVC Options Palette, including creating several settings styles for the Chop command.

Before calling the command, one or more solids can be selected. On one of the solids, you can pre-select one flat face or one edge (Use CTRL to select). The program will use these objects so as not to ask unnecessary questions. All objects other than solids will be ignored. If you want to cut a lot of solids at once, then you definitely need to select them in advance, before calling the Chop command.

Next, call the Chop command (just write CH in the command line).

You can configure the program so that the settings dialog is opened first.

Further program requests depend on the configured operating mode.

If no solids have been selected in advance, then the program will ask you to select a starting flat face or edge of the solid. In the query options, you can change the mode and switch the settings style.

If cutting is performed along a curved edge of a solid, and a fixed cutting step is specified, then the program will need the starting point of cutting from the user. Accordingly, stubs will remain at opposite ends of the edge.

Next, you may need to select solids (if they are not already selected).

This is followed by a request for the length of the piece (cutting step) or the number of pieces. The program will show on the command line what the slicing formula turns out to be - how many pieces of which length will turn out and with what stub. The length request is disabled by default and the value from the current chop-style is used.

If part numbering with a prefix is configured, it is still possible to request a prefix.

After all the preparation, the program will begin to cut the solid into pieces and assign layers and names to the resulting parts.

If an error occurs during cutting, the program will ask you if you should continue trying to cut. Many solids have places where Autodesk® AutoCAD® is not able to make a cut. In the process of its work, the program transfers the solid to the beginning of the WCS world coordinate system and then returns the pieces to their place. But if a failure occurs, then perhaps you will find pieces at the origin.

The remaining stubs (part of the solid, from which pieces of a given size were not learned) can be saved in the drawing and assigned to a separate layer.

The command may number the pieces or ribs in the order they were cut. The stubs are not numbered. Identical parts are given the same numbers.

Watch the messages on the command line - without this, you will not be able to understand why the program does not work the way you wanted.

Commands

| Ribbon/Toolbar Icon | Command | Command Description |

|---|---|---|

|

ChE |

Chop Edge. Cut a solid into same length pieces along edge |

|

StSt |

Stair-step. Make stair-step from a flat solid. Orthogonal side-faces |

|

Ch |

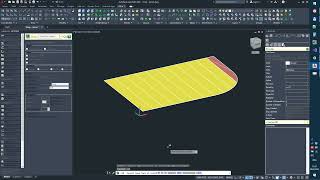

Chop. Cut 3D details into flat pieces |

Installation/Uninstallation

The installer that ran when you downloaded this app/plug-in from the Autodesk App Store will start installing the app/plug-in. OR, simply double-click the downloaded installer to install the app/plugin. You may need to restart the Autodesk product to activate the app/plug-in. To uninstall this plug-in, exit the Autodesk product if you are currently running it, simply rerun the installer, and select the "Uninstall" button. OR, click Control Panel > Programs > Programs and Features (Windows 7/8.1/10/11) and uninstall as you would any other application from your system.

Please read the FAQ if there is any problem.

Additional Information

Using the command Stair-Step (StSt):

The command should only be used for sheet material parts like ply, MDF, chipboard, and sheet metal. Such parts always have 2 large flat parallel surfaces - those that remain from the sheet of the source material. Often such parts are made on CNC milling machines that cannot tilt the cutter. Therefore, the ends of the parts must be perpendicular to the main planes. This command is intended just for modeling such details. It works like this:

-

We find the main (largest) plane.

-

We lay out the solid with this plane in XY (as the part will lie on the CNC machine).

-

We make two sections - one at zero in Z, the second at the very top of the solid (in fact, the program deliberately shifts the sections by 0.00001 inside the body, but this is almost not noticeable)

-

We extend both sections into new solids towards each other.

-

We find the intersection or union of these solids.

-

Voila! We have a completely new solid body that can be machined on a router. All its ends are perpendicular to the main plane. And it nowhere stands for the dimensions of the original solid. Unless, in the middle of its thickness, the original solid could have convex ends or holes in the ends. They won't.

-

We deploy a new solid back to the place of the old one.

-

We remove the old solid.

Understanding the principle of operation of this function will allow you to independently understand many oddities in the behavior of the program: why the end holes disappeared, why the inclined hole in the middle of the part began to look so strange, why the new solid protrudes beyond the original size on the convex end, why the grooves became through, why the segment of the sphere turned into a microscopic column, etc.

The current setting style of the Chop command determines which boolean operation the program will apply. If it is set to get a stepped solid inside the original one, then the operation of intersection (_Intersect) will be applied. If it is set to get a stepped solid outside of the original one, union (_Union) will be applied.

The command takes into work not one detail, but everything that you have chosen. You can select parts before calling the STST command. The original solids are always removed.

Known Issues

If the base curve is more than 180 degrees arc, circle, closed curve, or a winding spline, then in these cases the clipping planes will cut solid in several places. This causes a lot of problems. Unfortunately, this problem cannot be solved even in theory. The cut plane is infinite. The first cut at the start of the solid may cut off its tail. The tail will record in stubs and the last sections will be nothing left to cut. The program will attempt to miss sections that intersect the base curve several times. The program will first cut the solid in simple places and then return to the complex, in the hope that the large piece is not already so bent. But often such simple places do not exist. Then the program will alert you that something was wrong. And if you do not stop cutting, then inevitably arise extra slices and incorrect stubs. I recommend that in such cases, make the first cuts alone, ordinary Slice command. And then call ChopEdge for each piece.

Contact

Author/Company Information

Support Information

Support is provided by e-mail avc.programming@gmail.com

You can ask any questions about the work of A>V>C> programs, their installation and configuration, optimization of the work of engineers, and setting up business processes in the exhibition business. Help is provided to all users, regardless of whether they made a donation or not. Any suggestions and comments are welcome for further improvement of the programs.

The main method of communication is e-mail. You can write in any language. If you do not write in English, then write in short, simple but complete sentences without abbreviations and without special terms.

Do not forget to attach the problem dwg-file to the letter.

Telegram: @avc_programming

WhatsApp: A V C Programming

Version History

| Version Number | Version Description |

|---|---|

|

2024.03.00 |

AutoCAD 2026 compatibility |

|

2023.11.01 |

All updates for November 2023. |

|

2023.2.1 |

Added 2024 support. |

|

2022.3.1 |

New licensing system. |

|

2020.2 |

Added 2022 support (No change in version number). |

|

2019.3.4 |

Compatible with AutoCAD 2020 New activation system |

|

2018.3 |

Compatible with AutoCAD 2019 Fixed: StSt error (from tolerance) |

|

2017.3.0 |

Compatible with Autodesk® AutoCAD® 2019 |

|

1.3 |

Initial release |